Mechanical Subcontracting

Do not hesitate to contact us to receive a detailed offer.

Our services:

Quality Controls

Equipments:

- Keyence LM-1100

- MITUTOYO CRYSTA-Apex S 574

- Marcel-Aubert OPENSYS 175 & 186S

- TESA-HITE 700

- Etalon Derby 454

Machinery Park

HAAS VF4

Axis: 3 + 4th additional axis on Haas divider (HRT210)

Spindle: 10’000 rpm

Loader: 20 BT40 tools

Stroke X, Y, Z: 1270 x 508 x 635

Table: 1321 x 457

HAAS VM2

Axis: 3 + 4th and 5th additional Axis on Haas bi-spindle divider (TSC2)

Spindle: 12’000 rpm

Loader: 40 tools BT40

Stroke X, Y, Z: 762 x 508 x 508

Table: 914 x 457

HMI: Alphacam + Visual quick code

HAAS VM2

Axis: 3

Spindle: 12000 rpm

Loader: 25 tools CT40

Stroke X, Y, Z: 762 x 508 x 508

Table: 914 x 457

HMI: Alphacam + Visual quick code

MORI SEIKI NV5000

Axis: 3 + 4th and 5th additional Axis on Nikon divider

Spindle: 14000 rpm

Loader: 25 tools BT40

Stroke X, Y, Z: 800 x 510 x 510

Table: 1100 x 600

HMI: Alphacam + CAPPS

MORI SEIKI NMV3000

Axis: 5

Spindle: 12’000 rpm

Loader: 60 tools BT40

Stroke X, Y, Z: 500 x 350 x 510

Table: B axis + 160 ° – -180 ° and C axis 360 °

HMI: Alphacam + Mapps II

MORI SEIKI ACCUMILL 4000

Axis: 3

Spindle: 12’000 rpm

Loader: 20 tools BT30

Stroke X, Y, Z: 560 x 430 x 350

MORI SEIKI ZT1500 YB

Double spindles, double turrets

Spindle: 6’000 rpm

Loader: 2 x 16 tools VDI40

Bar passage: Ø 65mm

Max. milling Ø: 190 mm

Machining length: 235 mm

Distance between spindles: 1000 mm

Resupply: LNS Sprint S3 (3m bars)

IHM: Alphacam + Mapps II

SCHAUBLIN 302

Maximum turning diameter: 200 mm

Turning length: 200 mm

Max distance between points: 220 mm

Spindle speed range: 50 – 8’000 rpm

Bar passage: Ø 14.5 mm / Ø 19 mm

Transverse stroke, X axis: 150 mm

Longitudinal stroke, Z axis: 240 mm

Max speed: 6’000 rpm

SCHAUBLIN 842

Maximum turning diameter: 300 mm

Stroke X: 400 mm

Max distance between points: 470 mm

Bar passage: Ø 42 mm

Spindle speed range: 50 – 6’000 rpm

COLCHESTER Master VS 3250

SCHAUBLIN 110 CNC

Bar passage: Ø 32 mm

Spindle: 6000 rpm

Turrets: 8

Control: Fanuc

SCHAUBLIN 102 CNC

Bar passage: Ø 16 mm

Spindle: 5000 rpm

Control: Siemens

SCHAUBLIN 150

Traditional turning

Control: Heidenhaim ND780

FEHLMAN PICOMAX 54 CNC

Milling, drilling, tapping, reaming

Control: Heidenhain

OKAMOTO ACC55DX

Grinder/Glider

EWAG WS-11

Grinder/Glider

HUGI F-160

Grinder/Glider

KLAGER HAS 200

Saw Band 0.9 x 2720

Cutting dimensions: 220 x 220

PEMAMO MDR 120

PEMAMO 814 and 220 honing machines

Ø 0.6 to 1.5 mm respectively and from Ø 1.5 to 21 mm

NTX 1000S (2x)

Axis: 5 simultaneous Axis

Loader: 76 tools Capto C5

Spindle: 30000 rpm

Bar passage: 65 mm

Tightening Pin: HAINBUCH or mandrel

Tightening Rework Unit: YERLY or mandrel

Ravitaler: LNS Quik Load Servo III

Control : Fanuc 3 li-B5

508 MT (3x)

Axis: 5 simultaneous Axis

Turret recovery

Tool store: 48 tools C4

Spindle: 30000 rpm

Bar passage: Ø 42 mm

Spindle Clamp: HAINBUCH

Resupply: IEMCA Boss 552-HD

Control: Fanuc

408S2 (4x)

Axis: 5 simultaneous Axis

Recovery turret

Tool store: 48 tools C4

Spindle: 30000 rpm

Bar passage: Ø 42 mm

Spindle Clamp: HAINBUCH

Resupply: IEMCA Boss 552-HD

Control: Fanuc

CUT 2000 OILTECH

Stroke X, Y, Z: 350 x 250 x 256 mm

Angle / Height of cut: 30° / 100 mm

Wire from 0.05 to 0.30 mm

Max. dimension L, P, H: 750 x 550 x 250 mm

HMI: PEPS Wire CAMTEK + Vision 5

FORM 20

Stroke X, Y, Z: 350 x 250 x 250 mm

Axis C

Loader: 4-electrode

EROWA clamping

Max. dimension L, P, H: 800 x 500 x 265 mm

HMI: AC Form HMI

CUT 200 MS

Stroke X, Y, Z: 350 x 220 x 220 mm

Wire from 0.07 to 0.25 mm

Max. dimension L, P, H: 1000 x 550 x 220 mm

IHM : PEPS Wire CAMTEK + AC Cut HMI

CUT 200 SP

Stroke X, Y, Z: 350 x 220 x 220 mm

Wire from 0.15 to 0.25 mm

Max. dimension L, P, H: 1000 x 550 x 220 mm

IHM : PEPS Wire CAMTEK + AC Cut HMI

DRILL 20

Stroke X, Y, Z : 300 x 200 x 300 mm

Electrode Ø : from 0.1 to 2 mm

IHM : AC Drill V8

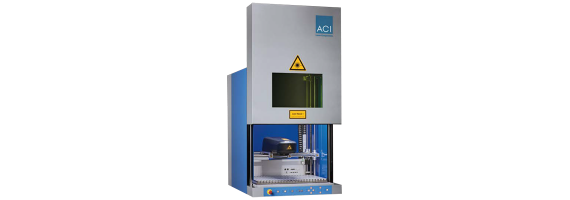

AXNUM Workstation Professional (ACI) (2x)

Tray 600 x 600 mm

X-axis: 400 mm

Z-axis: 440 mm

Rotation axis for circular marking

Laser class: 1